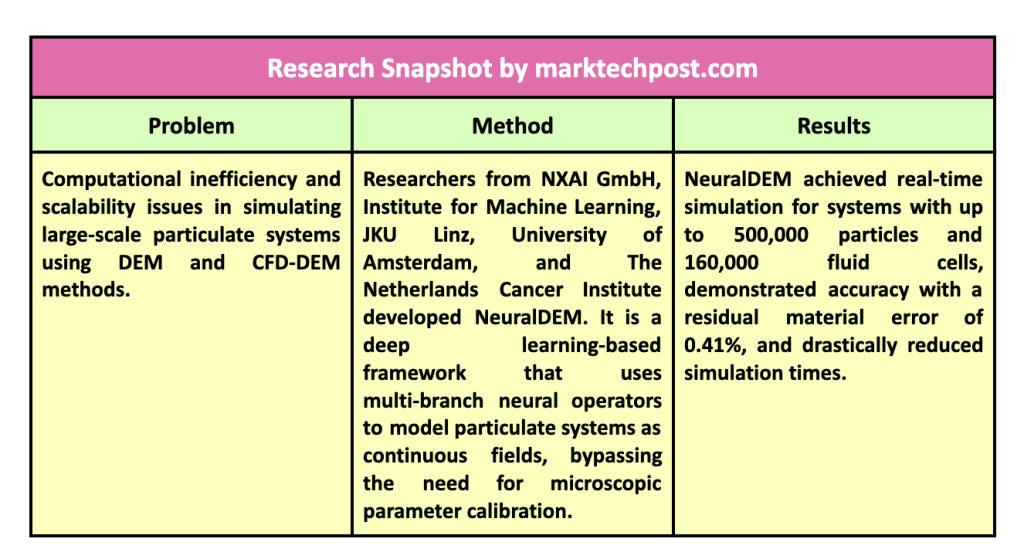

Advances in particle flow simulation have had a significant impact on industries ranging from mining to pharmaceuticals. Particle systems consist of granular materials that interact with each other and with surrounding fluids, and their accurate modeling is essential to optimize processes. However, traditional numerical methods such as the Discrete Element Method (DEM) face substantial computational limitations. These methods track the motions and interactions of particles by solving Newton's equations of motion, which requires enormous computational resources. Coupled with fluid dynamics simulations, DEM becomes even more demanding, making large-scale or long-duration simulations impractical for real-time applications.

One of the central challenges in this domain lies in the multiscale nature of particle systems. Simulating millions of interacting particles over time requires microsecond-scale time steps, causing simulations to run for hours or even days. Additionally, DEM requires extensive calibration of microscopic material properties, such as friction coefficients, to achieve accurate macroscopic results. This calibration is tedious and error-prone, further complicating the integration of these simulations into iterative industrial workflows. Existing methods, although correct, need help adapting to the enormous computational demands of industrial systems with more than 500,000 particles or fluid cells.

Researchers from NXAI GmbH, the Institute for Machine Learning, JKU Linz, the University of Amsterdam and the Netherlands Cancer Institute developed <a target="_blank" href="https://nx-ai.github.io/NeuralDEM/”>NeuralDEM. NeuralDEM employs deep learning to replace the computationally intensive routines of DEM and CFD-DEM. This framework models particle dynamics and fluid interactions as continuous fields, significantly reducing computational complexity. By leveraging multi-branch neural operators, NeuralDEM directly predicts macroscopic behaviors such as flow regimes and transport phenomena without requiring detailed calibration of microscopic parameters. This ability to generalize across various system conditions is a key innovation, allowing seamless simulation of different geometries, particle properties and flow conditions.

The architecture of NeuralDEM is based on the concept of multi-branch transformers. These neural operators process multiple physical phenomena simultaneously. For example, the framework uses primary branches to model core physics such as particle displacement and fluid velocity, while auxiliary branches handle macroscopic quantities such as particle transport and mixing. This design allows NeuralDEM to simulate highly complex scenarios involving 500,000 particles and 160,000 fluid cells, as demonstrated in the fluidized bed reactor experiments. Unlike traditional DEM, NeuralDEM operates on coarser time intervals, achieving real-time simulation performance for long-running processes.

In experimental validation, NeuralDEM was applied to fluidized bed and hopper reactor systems, demonstrating its versatility and efficiency. In hopper simulations with 250,000 particles, NeuralDEM accurately captured macroscopic flow phenomena such as mass flow and funnel flow regimes. It successfully predicted outflow rates, drainage times, and residual material volumes with minimal deviation from actual DEM results. For example, NeuralDEM estimated drainage times within 0.19 seconds of DEM calculations and predicted residual material volumes with an average error of 0.41%. These simulations required only a fraction of the computational time compared to DEM, achieving real-time performance.

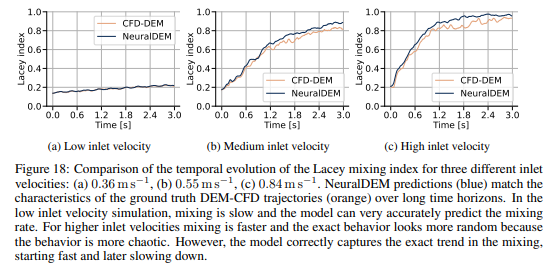

In fluidized bed reactors, NeuralDEM demonstrated its ability to model fast and transient phenomena involving strong interactions between particles and fluids. Simulations with 500,000 particles and 160,000 fluid cells accurately replicated mixing behaviors, residence times, and dynamic flow patterns. The researchers highlighted NeuralDEM's ability to simulate 28-second trajectories in just 2,800 machine learning time steps, a significant reduction compared to traditional methods. This efficiency positions NeuralDEM as a transformative tool for industrial applications that require fast and reliable process modeling.

The research presents key findings that highlight the potential of NeuralDEM as a revolutionary technology:

- Scalability: Successfully simulated systems with up to 500,000 particles and 160,000 fluid cells, significantly expanding the applicability of numerical modeling to industrial-scale problems.

- Accuracy: High fidelity was achieved in modeling complex flow regimes, with errors as low as 0.41% for residual material predictions.

- Efficiency: Reduction of computational times from hours to real time, making iterative design and optimization feasible.

- Generality: Demonstrated robustness across various system parameters, including geometries, material properties, and flow rates.

- Innovation: Multi-branch neural operators capable of decoupling microscopic and macroscopic modeling were introduced to improve flexibility and accuracy.

In conclusion, NeuralDEM represents a step forward in the simulation of particle flows, closing the gap between computational feasibility and industrial applicability. By leveraging deep learning to address the limitations of traditional methods, NeuralDEM has redefined the numerical modeling landscape. Its efficiency, scalability and precision make it a fundamental tool for industries seeking to optimize processes and accelerate engineering cycles. The results of this research show a clear path to integrating advanced simulations into real-world workflows, opening up new possibilities for innovation in the modeling of particle systems.

look at the Paper and <a target="_blank" href="https://nx-ai.github.io/NeuralDEM/” target=”_blank” rel=”noreferrer noopener”>Project. All credit for this research goes to the researchers of this project. Also, don't forget to follow us on <a target="_blank" href="https://twitter.com/Marktechpost”>twitter and join our Telegram channel and LinkedIn Grabove. If you like our work, you will love our information sheet.. Don't forget to join our SubReddit over 55,000ml.

(<a target="_blank" href="https://landing.deepset.ai/webinar-implementing-idp-with-genai-in-financial-services?utm_campaign=2411%20-%20webinar%20-%20credX%20-%20IDP%20with%20GenAI%20in%20Financial%20Services&utm_source=marktechpost&utm_medium=newsletter” target=”_blank” rel=”noreferrer noopener”>FREE WEBINAR on ai) <a target="_blank" href="https://landing.deepset.ai/webinar-implementing-idp-with-genai-in-financial-services?utm_campaign=2411%20-%20webinar%20-%20credX%20-%20IDP%20with%20GenAI%20in%20Financial%20Services&utm_source=marktechpost&utm_medium=newsletter” target=”_blank” rel=”noreferrer noopener”>Implementation of intelligent document processing with GenAI in financial services and real estate transactions– <a target="_blank" href="https://landing.deepset.ai/webinar-implementing-idp-with-genai-in-financial-services?utm_campaign=2411%20-%20webinar%20-%20credX%20-%20IDP%20with%20GenAI%20in%20Financial%20Services&utm_source=marktechpost&utm_medium=banner-ad-desktop” target=”_blank” rel=”noreferrer noopener”>From framework to production

Nikhil is an internal consultant at Marktechpost. He is pursuing an integrated double degree in Materials at the Indian Institute of technology Kharagpur. Nikhil is an ai/ML enthusiast who is always researching applications in fields like biomaterials and biomedical science. With a strong background in materials science, he is exploring new advances and creating opportunities to contribute.

<script async src="//platform.twitter.com/widgets.js” charset=”utf-8″>